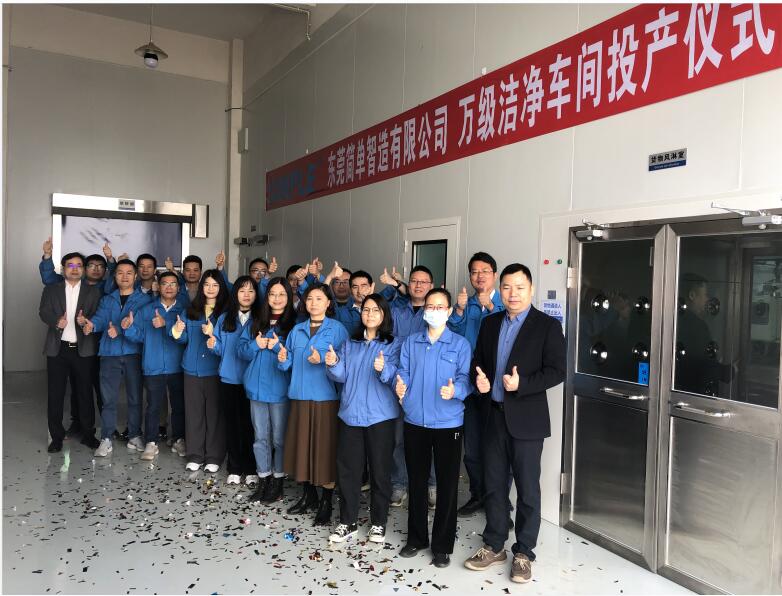

December 10, 2022, Simple manufacturing's clean room was put into use officially, the representatives from relative depts attended in the opening ceremony.

The clean room was built with 10,000 level standard including machine rooms, power systems, HVAC systems, and purification systems, equipped with the EPS steel plate formed body to be assembled on site, arched inner walls, purification lights on the top, large glass windows and the epoxy self-flowing floor well prevent the dust accumulation, the air circulation system working 24 hours ensures the inside air cleanliness.

Also, the air shower rooms set up at the entrance to shower people and goods to avoid dust bring in.

The particulates, harmful air, bacteria, temperature, cleanliness, pressure, air velocity, noise, vibration, lighting, and static electricity etc. can be controlled at a demand range in the clean room. It provides a much more stable and reliable environment for production, better satisfy customers' needs especially in medical consumables production.